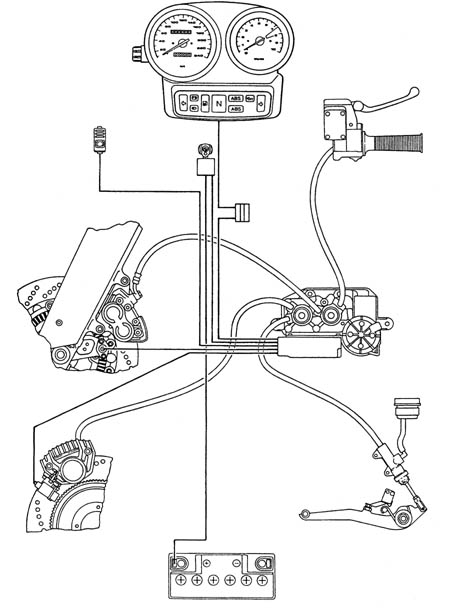

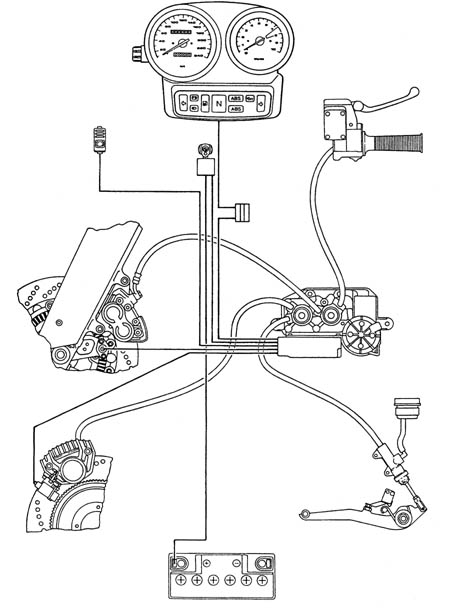

This entire unit is favourably positioned, from the point of view of the centre of gravity, near the battery and thus does not adversely affect the handling of the motorcycle.

The following information is as supplied by BMWNA. The order of the pages is not clear and there seems to be some missing information that I'll try to fill in later.

The ABS II, jointly developed by BMW and FAG I, is comprised of the following

components:

Owing to its compact design, the ABS II is only half as heavy as the ABS I (i.e. 5.3 kg as compared with slightly less than 10 kg) and is characterised by its greatly enhanced control convenience.

The rotating speed of the front and rear wheels are measured

inductively.

The sensor itself is composed of an iron core about which a coil

is wrapped. Direct current flows through the coil, in the process creating a

magnetic field.

A sprocket securely mounted to the wheel is routed past the

sensor which transforms the direct current into a sinusoidal current by virtue

of the change in geometry (tooth gullet and tooth tip ). The frequency of this

sinusoidal current is a direct measure of the rotating speed of the wheel and is

processed as such by the control unit.

The pressure modulator ensures adherence to the preset

brake pressure and is designed as a hydraulic/mechanical actuator.

The brake pressure required is modulated by way of specific

variation in volume. The pressure modulator operates within preset limits

independently of the pressure and temperature in the brake system.

The pistons in the pressure modulator are powered by an electric

motor which causes a crosswise shaft to turn.

An

electronically controlled friction clutch is mounted on this shaft for each of

the pistons (front and rear wheel). The other end of the clutch forms a direct

connection with the steel strutted piston via a tie element.

The amount of current applied to the friction clutch is a direct measure

of the power with which the steel strutted pistons are caused to change in

volume.

A separate displacement sensor records the

distance travelled by the piston and makes available this value to the control

unit as a control variable.

Advantage: faster and, as a

consequence, decoupled control characteristics.

All

commands for activating the pressure modulator come from the control unit.

The control unit of the ABS I I consists of three

microcomputers.

Two of them function as working

processors, the third one as a watchdog processor. The two working processors

are identical in design, perform the same computing operations and constantly

compare the results obtained with one another.

The system

switches off if there is a discrepancy in the data computed by the two working

processors during operation of the motorcycle. This is indicated to the

motorcycle rider by the ABS Check Control light blinking.

In this case as well, the braking system is fully operational, however

without the ABS. If a discrepancy occurs in the data generated by the two

working

processors during a control sequence, the braking action initiated

is carried out in any event by the working processor still intact

function.

Which of the two working processors is still

functioning properly in this case is decided by the control or watchdog

processor.

This is followed by the system switching off.

The watchdog processor is not identical in design to the working processors,

however it performs the same computing operations. Consequently, the watchdog

processor is capable of deciding which of the two working processors has

provided the correct data and affords the respective working processor the

possibility of completing the control sequence.

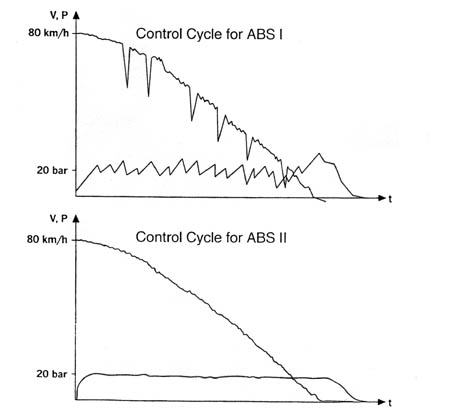

The closed-loop control circuit consists of signal

processing by the sensors and automatic control electronics which activate the

electro-motor-powered pressure modulator in the event of overbraking by the

wheel.

If the ABS control unit detects that wheel locking

is about to take place on the basis of impulses being received from the

rotating-speed sensors, it activates the motor of the clutch shaft. At the same

time, the electro-magnetically controlled friction clutch of the respective

brake circuit mounted to the clutch shaft is activated.

Depending on the frictional torque generated by the control unit in this

clutch, the plunger piston in the pressure modulator is pulled downwards against

a spring resistance by a precisely defined amount.

The

resulting enlarged volume above the plunger piston results in the pressure

decrease required in the brake circuit. At the same time, the movement of the

reciprocating piston is recorded by the displacement sensor and forwarded to the

ABS control unit, which obtains the information needed concerning the position

of the piston in this manner and thus has a reference as to the relative brake

pressure in the brake circuit. This scanning takes place within the closed-loop

range every 8 ms and in the open-loop range every 4 ms.

The wheel is optimally decelerated just below the locking limit. This

control sequence is repeated every time the wheel is on the verge of

locking.

This system is the first system to enable

recognition of the relative pressure by virtue of the displacement sensor of the

reciprocating piston, with its corresponding position consequently making it

possible to operate the motorcycle in accordance with any brake pressure curve

in keeping with the respective riding conditions.

Based

on the rotating-speed information coming from both wheels, this system is also

capable of detecting lifting of the rear brake when the brakes are fully applied

and preventing th is by correspondingly regulating the pressure in the front

wheel brake circuit.

Owing to the fact that this system

employs a plunger piston, the brake pressure can be decreased to 0 bar, thus

ensuring dependable control behaviour on difficult riding surfaces, e.g. black

ice, gravel etc.

The following standard tests have been integrated in the

ABS II in order to fulfill BMW's high safety and security standard ("Every conceivable

system fault whether electrical, electronic, hydraulic or mechanical - must

enable the rider to sufficiently decelarate, even when the ABS is deactivated").

The ABS II is characterised by its compact design coupled

with high electromagnetic compatibility (E¯C), making it ideal for motorcycles.

It has only half the weight of ABS I and is optimally sited (i.e. motorcycle

handling is not adversely affected).

By virtue of the

triple-microprocessor system, a level of safety and security is attained which

is unparalleled in ABS systems to date.

The ABS I I

features outstanding control convenience, offering the rifder a valuable,

easy-to-use tool whenever needed.

The perfected software

enables even extreme braking conditions, e.g. rearing of the rear wheel, to be

compensated. In addition, safety while riding on difficult surfaces, e.g.

alternately wet, dry or slippery surfaces, is enhanced.

The displacement measurement of the reciprocating piston enables the

rotating speed of the wheel to be maintained just below the locking limit. This

ensures complete, virtually optimal utilisation of tyre-road traction.

All of the above features of the ABS demonstrate once again that

BMW is the innovative pioneer when it comes to state-of-the-art motorcycle

safety and reliability. Through ongoing product development, BMW will maintain

its leading edge in the future.